|

Orson Group Co., Limited

|

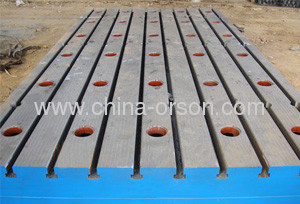

Rivet Weld Plate

| Payment Terms: | T/T,L/C,D/A |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rivet Weld Plate should be after two artificial effectiveness (annealing treatment) or natural aging 2-3 years, in order to reduce casting stress, imp

Abstract:

Rivet Weld Plate should be after two artificial effectiveness (annealing treatment) or natural aging 2-3 years, in order to reduce casting stress, improve maohan plate work surface hardness and wear resistance. Make maohan plate accuracy stability, wear-resisting performance is good. A qualified maohan plate, must strict after each link, each a link in the small differences, finally all affect the quality of the products. Our company is specialized in manufacturing all kinds of cast iron plate, cast iron platform, crossed platform, crossed flat measuring, careful to every detail, and carefully make each product.

Maohan plate work surfaces should be sand hole, porosity, crack, slag and shrinkage defects of castings. All kinds of casting surface should be clear sand, and the surface is flat, paint firm. Each edge should fix blunt. Cast iron platform in accuracy level below "00" class platform on the work for less than 15 mm diameter of sand hole permission to use the same materials plugging, its hardness should be lower than the surrounding material hardness. In working face of jam part should be not more than all around, the distance between each other should be no less than 80 mm

USES:

Rivet Weld Plate is used for riveting and welding process of the foundation slab, the work surface hole and T slot, hole is used to clean up maohan some of the iron slag and welding waste, T slot is mainly used to fixed weldments.

Material:

Rivet Weld Plate material for high strength cast iron HT200-300, face hardness for HB170-240, after two artificial processing (artificial annealing 600 degrees - 700 degrees and natural aging 2-3 years) using the product accuracy stability, wear-resisting performance is good.

Specification:

100 mm * 100 mm - 3000 mm * 6000 mm (special specifications according to buyer's drawing production).

Accuracy:

According to the national standard metrological verification code execution, respectively 0, 1, 2, 3 four ranks.

0 level grade 1 flat platform in each edge is 25mm square within the scope of no less than 25 points.

Level 2 flat platform in each edge is 25 mm square within the scope of not less than 20 point.

Level 3 flat platform in each edge is 25 mm square within the scope of not less than 12 o 'clock.

(mm) | ( μm ) | |||

1 | 2 | 3 | ||

1200 × 1000 | 20 | 39 | 96 | |

1500 × 1000 | 24 | 48 | 120 | |

1500 × 1500 | 25 | 50 | 125 | |

2000 × 1000 | 26 | 52 | 129 | |

2000 × 1500 | 56 | 140 | ||

2000 × 2000 | 60 | 152 | 230 | |

2500 × 1500 | 64 | 152 | 230 | |

2500 × 2000 | 68 | 168 | 248 | |

2500 × 2500 | 72 | 180 | 270 | |

3000 × 1000 | 168 | 248 | ||

3000 × 1500 | 174 | 254 | ||

3000 × 2000 | 184 | 275 | ||

3000 × 2500 | 186 | 276 | ||

3000 × 3000 | 210 | 300 | ||

4000 × 1000 | 210 | 300 | ||

4000 × 1500 | 210 | 300 | ||

4000 × 2000 | 219 | 340 | ||

4000 × 2500 | 228 | 340 | ||

4000 × 3000 | 240 | 360 | ||

5000 × 1500 | 249 | 370 | ||

5000 × 2000 | 255 | 375 | ||

5000 × 2500 | 264 | 390 | ||

5000 × 3000 | 287 | 420 | ||

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!